FAQS

📞 1 225-424-8804FAQS

How do I choose between carbide and diamond rock saw?

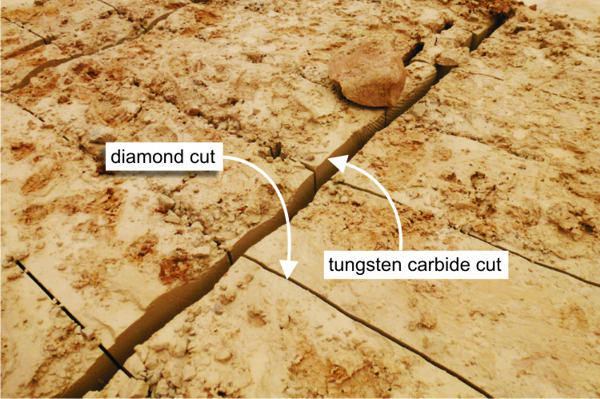

Comparison between tungsten carbide and diamond saw cuts

Surface finish of tungsten-carbide rocksaw cuts

In most cases, unfortunately, there isn't a simple answer to this question.

Hardness of Material to be cut

While it is safe to say that carbide saws are unsuitable for materials above 60 MPa and diamond saws are unsuitable for compressive strengths below 15 MPa, it is the region in between, which is encountered the most, where it is the hardest to decide.

In most cases the really decisive factors are external considerations as:-

Availability of Water

- carbide does not have to have water available, for diamond it is a mustNoise and Vibration

- carbide tipped rock saws are noisy while diamond is smooth and relatively silentValue of the Cut Product

- if you are selling the rock you cut, then remember that about 10% of your product gets wasted on width of cut when carbide rock saw is used. This become less than 2% for diamond tipped rock sawSurface finish

- the surface finish achieved with diamond rocksaws is much smoother than from tungsten carbide, and can produce finished blocks and slabsproductivity, labour and fuel costs

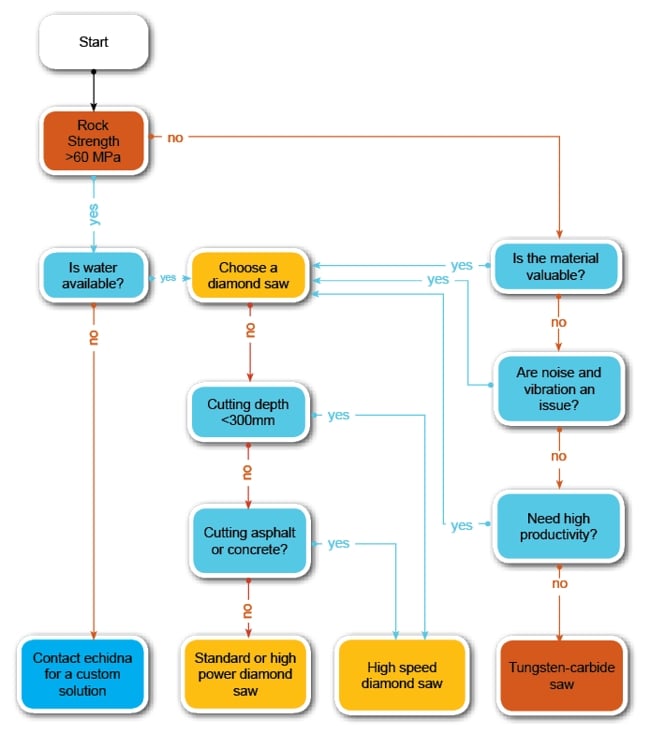

- in terms of consumables only a carbide tipped rock saw is cheaper to run than a diamond. But it cuts substantially slower than the diamond and saving on materials is soon overshadowed by spending on labour and fuel costsThe chart below is intended to give some guidance as to how to choose between the different types of rocksaws available.