Tunnels & Mines

Tunnels & Mines

Challenges in Tunneling Works

Tunnels provide a variety of challenges. The types of work which our equipment is suited for includes

Enclosed Spaces

The nature of tunnels is that they are enclosed spaces, so the size of the equipment may be limited, and the cutting may be at any angle. They also tend to be long.

The first issue means that attachments used should be selected to maximise productivity, by completely utilising the power available from the excavator. The high performance rocksaws from Echidna's High Speed and High Power series provide this opportunity.

Cutting horizontally requires the operator to be able to choose the direction of blade spin. If the blade spins the wrong way, it pulls into the cut and jambs. All of our rocksaws come with reversible blade spin.

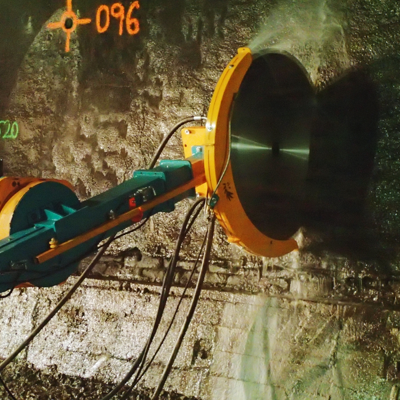

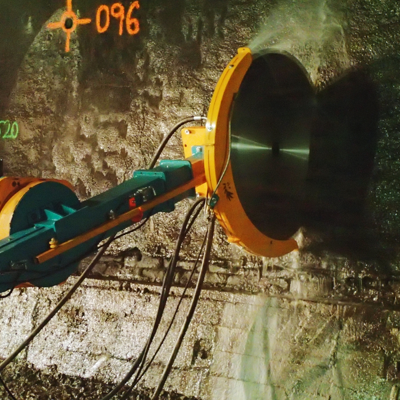

Cutting at other angles is impossible without additional equipment. Echidna makes standard and custom built rotators, tilts, rails and telescopic arms that allow a great deal of flexibility in cutting at angles.

Vibrations

Modification of existing tunnels can cause damage to existing structures, due to vibration. Diamond rocksaws cut smoothly and are far less likely to cause damage. Rock saw cuts are an effective way of limiting the propagation of vibrations, in many cases allowing hammers to be used without damage.

Services trenches may be required to run the length of a tunnel. Sometimes for many kilometres.

For tunnels with a level floor, a rail mounted, self propelled system, such as our CS5 may be a good solution. Such systems offer high precision, maximum productivity. They can be customised to cut at angles, and with dual blades. Being fully automated once set up, these cutting systems do not suffer from fatigue or boredom, and the result is faster cutting with much reduced blade wear and lower operator costs.

Safety

Safety, access and visibility are other factors to consider for work in tunnels. Echidna builds remote controlled machines - stand-alone or as excavator attachments. Remote operation can allow the attachment to be applied with precision, while keeping personnel well away from the cutting zone.